Protecting Long-Term Asset Performance with Durable Design & Corrosion Mitigation Strategies

In infrastructure, failure isn’t always immediate, it often begins quietly, at the design stage. One of the most significant threats to long-term structural performance is corrosion. Yet despite its known risks, corrosion mitigation is often addressed too late in the project lifecycle, when repair costs are high and asset integrity is already compromised.

In this post, we explore how future-proofing your infrastructure against corrosion starts with intelligent, durable design. We’ll walk through the role of durable material selection, corrosion management information, and how construction quality assurance can help engineers and asset managers avoid the costliest consequences of corrosion before the first slab is poured.

This is especially relevant for developers, structural engineers, architects, and government bodies managing infrastructure in harsh or marine environments across Australia.

Why Design Matters in Corrosion Mitigation

Corrosion isn’t just a material issue, it’s a design issue. Inadequate detailing, poor material choices, or failure to assess environmental conditions can all lead to early deterioration. Many large-scale failures stem from overlooked risks during the concept or design phase.

Common design flaws that contribute to corrosion:

- Inadequate cover for reinforced concrete

- Poor detailing that allows water ingress

- Incorrect fastener or fixture specification

- Lack of understanding of corrosivity zones (e.g., coastal vs inland)

- Using incompatible materials together

The increase in the cost associated with overlooking these common issues has been summarised in de Sitter’s “Law of Fives”, which states that “one dollar spent in Initial Design and Construction equals $5 in Preventive Maintenance equals $25 in Repairs and Maintenance equals $125 in Major Repairs and Renovations”

As de Sitter stated, these values should not be taken exactly, but rather point out where attention must be focused, i.e., initial design and construction, and preventive maintenance (inspections, coating application, etc.). Hence, proactively integrating corrosion management information into the design process gives projects the best chance at long-term performance, reduced maintenance, and lifecycle cost savings.

The Importance of Corrosivity Assessment

Three elements are taken into consideration when designing a new plant or infrastructure: environmental corrosivity, material selection, and design and construction methods. So, before selecting materials or committing to a design, understanding the corrosive environment is critical. TECHT provides corrosivity assessments that consider:

- Environmental exposure categories (e.g., marine, industrial)

- Site-specific humidity, salinity, and rainfall

- Previous failure data in the area

- Corrosion rate modeling over time

These insights are used to produce Service Life Calculations, aligning with industry standards and providing clear expectations for asset durability.

Explore our corrosivity assessment services.

What Is a Durability Plan and Why Do You Need One?

A Durability Plan breaks down your project into different environments and identifies the individual corrosion risks each component faces. This tailored analysis results in a clear roadmap for:

- Detailing changes to avoid water traps or galvanic contact

- Material upgrades where required

- Specification of coatings, cathodic protection, or barriers

- Ongoing inspection and maintenance planning

By starting with a durability mindset, asset owners avoid costly remediation later and achieve greater reliability over the asset’s service life.

Consultation with stakeholders is crucial to properly discuss corrosion mechanisms

Material Testing & Specification Review

TECHT’s ArchiTECHT team conducts material testing and provides guidance on correct specification development, to ensure materials are fit for purpose in corrosive environments.

This includes:

- Laboratory analysis for chloride ingress, carbonation, and coating failure

- On-site inspection of existing materials

- Corrosion coupon testing

- Testing to AS and ISO standards

Whether you’re building near the ocean, in a high-humidity zone, or an industrial area with chemical exposure, smart specification reduces long-term risk and gives contractors clear guidance to execute your vision reliably.

Construction Quality Assurance & Control

Even the best designs can fail without proper execution. That’s why TECHT supports projects through construction with:

- Independent QA/QC inspection services

- Specification compliance checks

- Rapid issue resolution on-site

- Documentation for asset lifecycle maintenance

Our construction quality assurance services close the loop between design and performance, ensuring the corrosion mitigation strategies put on paper are delivered in the field.

Poor QA/QC can mean issues can develop unchecked.

Future-Proofing Starts with Design

If you want long-lasting, low-maintenance infrastructure, don’t wait until corrosion appears, design against it from day one.

From corrosivity assessments to specification reviews and QA/QC support, TECHT helps you deliver durable infrastructure backed by engineering intelligence.

Learn more about our approach to durable design engineering and corrosion mitigation on the ArchiTECHT service page, or contact TECHT to speak with a corrosion and durability specialist.

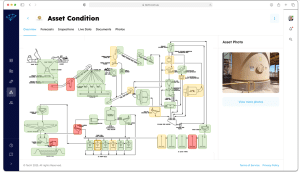

Implementation of IoT systems and software aims to streamline and simplify workflows